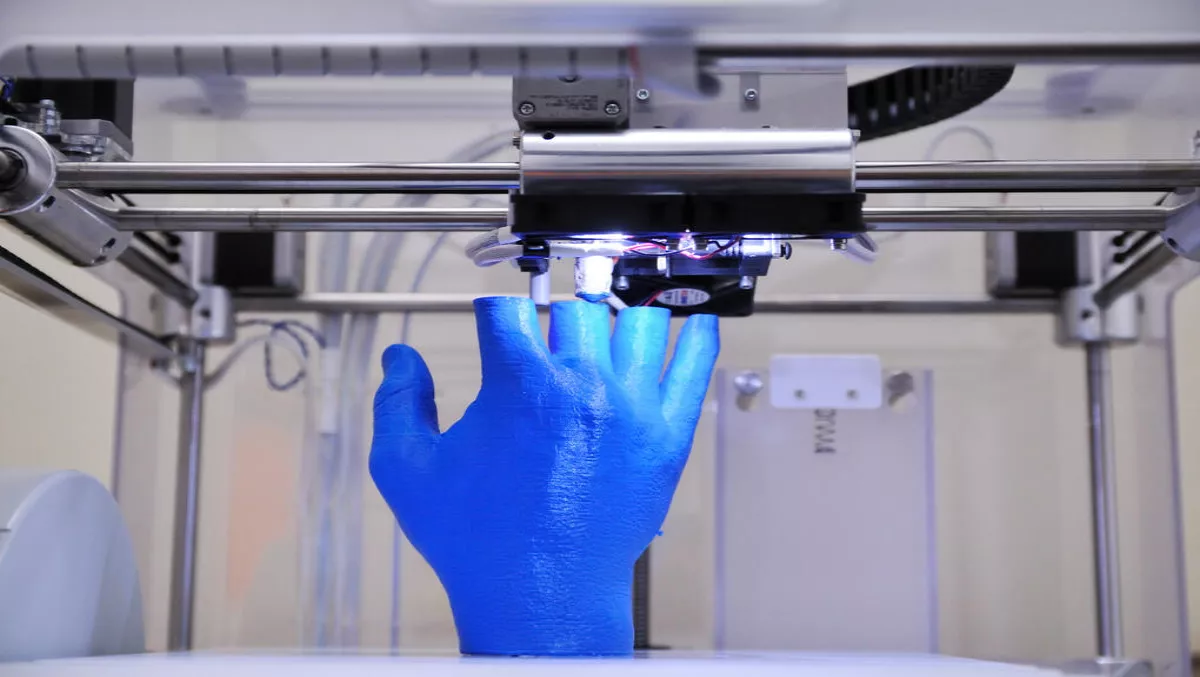

Northland businesses will benefit from an increased focus on high-tech, commercial 3D printing, thanks to a partnership between an entrepreneurial NorthTec student and Northland Inc.

Interested companies can access these facilities through Northland Inc's Regional Research Office (RRO), which is a direct channel that gives Northlanders access to research facilities and global expert advice.

Saransh Saxena, a NorthTec student who holds a Bachelor of Engineering (Mechanical) from University of Hertfordshire, UK, believes the technology, although an essential in the engineering, medical and science industries, is still underutilised.

Saxena believes Northland could use the technology to fund research.

“It's been around for a while but not a lot of work has gone into how best to use 3D-printing for research and for improved and cost-efficient product development beyond its current educational and training purposes,” Saxena says.

Joseph Stuart, the regional economic development agency's general manager for Business, Innovation and Growth, says this could be the start of a transformational initiative.

“We invite interested businesses (in Northland) to get in touch with us and work with us on this vital project which could change the way they do things. Currently 3D printing exists in pockets in Northland and we're targeting greater support through capital and expertise to undertake R - D into existing and new products and services," Stuart says.

"With this project we aim to engineer a dynamic shift in the way Northland companies deliver to customers and we believe it has the potential to produce very good outcomes,” Stuart concludes.

Rob Meadows, NorthTec lecturer in Project Management, Business Communications and Industry Projects, says the collaborative partnership between institutions and agencies hopes to develop long-term innovation, through both facilities and Saxena's technical knowledge and capacity.

Already Northland companies are using the 3D printing technology. SaltRiver Industries is using the technology to develop new-format waterjet systems for their jet boat manufacturing operations.

"It has proved to be an effective communication tool that allows others to quickly understand and participate in the design process. As we move into the prototype manufacture phase, we are using 3D-printing to reduce the cost associated with traditional foundry tooling, however computer aided design (CAD) skills are required to do anything meaningful with 3D-printing,” SaltRiver Industries' Richard Reynolds says.